About Cal Nano

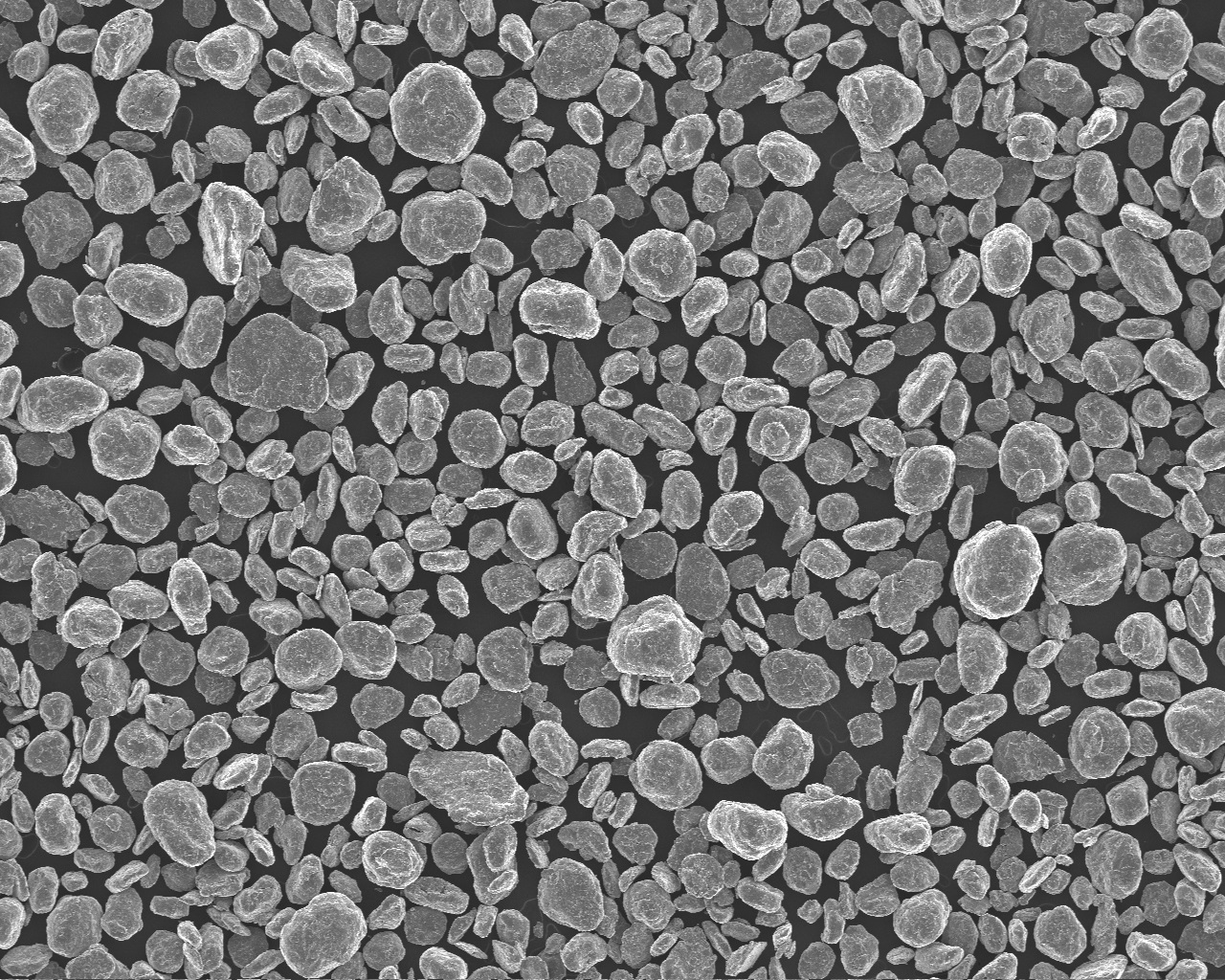

About Cal Nano **Latest Podcast on Cal Nano, SPS, and Cryomilling - Discover the Future of Advanced Materials with California Nanotechnologies! Click to Watch! Our Mission: Bringing next generation materials to market with cutting-edge technologies. Our Vision: At Cal Nano, we envision a world in which our advanced technologies are used to help make the most innovative products on this planet and beyond. We are trusted by global leaders to help push ...

High Strength SPS Graphite Tooling

High Strength SPS Graphite Tooling Tungsten Carbide Tooling

Tungsten Carbide Tooling Carbon Graphite Foil / Paper

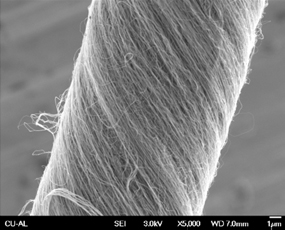

Carbon Graphite Foil / Paper Carbon Felt and Yarn

Carbon Felt and Yarn Spark Plasma Sintering Systems

Spark Plasma Sintering Systems SPS/FAST Modeling Software

SPS/FAST Modeling Software